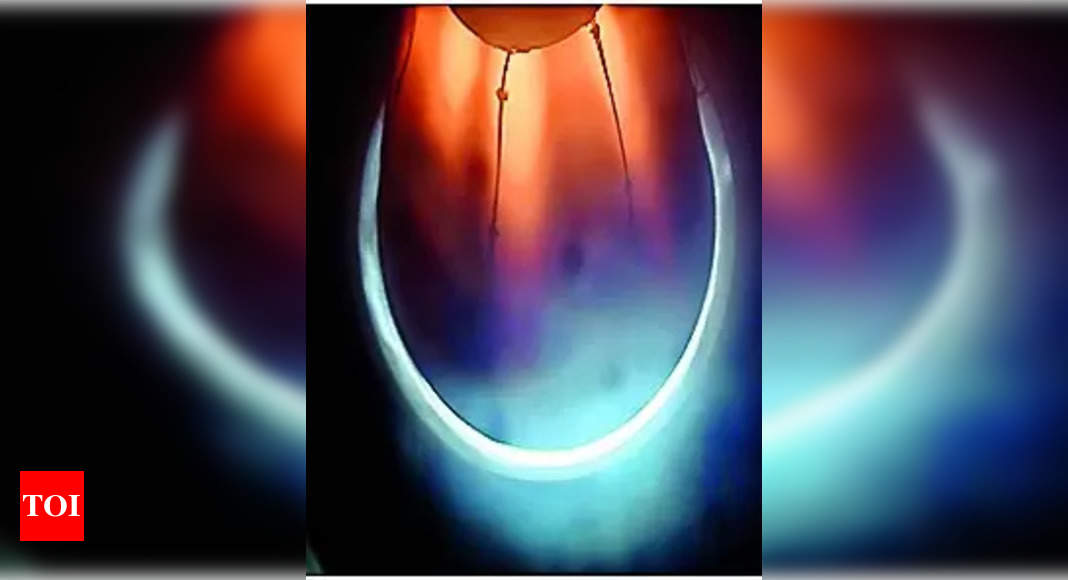

In a significant advancement, the Indian Space Research Organisation (ISRO) announced the successful development of a lightweight carbon-carbon (C-C) nozzle for rocket engines. The breakthrough innovation, accomplished by the Vikram Sarabhai Space Centre (VSSC), promises to enhance the vital parameters of rocket engines, including thrust levels, specific impulse, and thrust-to-weight ratios. With the utilization of advanced materials like carbon-carbon composites, VSSC has created a nozzle divergent with exceptional properties.

The C-C nozzle is lightweight, making it a game-changer in rocket engine technology. Utilizing processes such as carbonisation of green composites, chemical vapour infiltration, and high-temperature treatment, VSSC has produced a nozzle with low density, high specific strength, and excellent stiffness. Notably, the nozzle retains its mechanical properties even at elevated temperatures.

One of the key features of the C-C nozzle is its special anti-oxidation coating of silicon carbide. This coating extends its operational limits in oxidizing environments. The innovation not only reduces thermally induced stresses but also enhances corrosion resistance, allowing for extended operational temperature limits in hostile environments.

The potential impact of this development is significant, particularly for ISRO’s workhorse launcher, the Polar Satellite Launch Vehicle (PSLV). Currently, the PS4, the fourth stage of the PSLV, employs twin engines with nozzles made from Columbium alloy. However, by replacing these metallic divergent nozzles with C-C counterparts, a mass reduction of approximately 67% can be achieved. This substitution is projected to increase the payload capability of the PSLV by 15kg, a notable enhancement for space missions.

The successful testing of the C-C nozzle divergent marked a major milestone for ISRO. On March 19, a 60-second hot test was conducted at the high-altitude test (HAT) facility in ISRO Propulsion Complex (IPRC), Mahendragiri, confirming the system’s performance and hardware integrity. Subsequent tests, including a 200-second hot test on April 2, 2024, further validated the nozzle’s capabilities, with temperatures reaching 1216K, matching predictions.

The development of this advanced technology was a collaborative effort between ISRO’s Vikram Sarabhai Space Centre and Liquid Propulsion Systems Centre (LPSC) at Valiamala. The LPSC designed and configured the test, while the ISRO Propulsion Complex in Mahendragiri executed the instrumentation and testing at their high-altitude test facility.

The breakthrough achieved by ISRO in rocket engine technology opens up new possibilities for space exploration. It demonstrates the organization’s commitment to continuous innovation and improvement in the field, pushing the boundaries of what is possible in space missions.

Read More: [India aims to achieve debris-free space missions by 2030: ISRO chief](https://timesofindia.indiatimes.com/india/india-aims-to-achieve-debris-free-space-missions-by-2030-isro-chief/articleshow/109356772.cms)

[AI to rule all fields, time to be future-ready: ISRO chief](https://timesofindia.indiatimes.com/city/hyderabad/ai-to-rule-all-fields-time-to-be-future-ready-isro-chief/articleshow/109334671.cms)